About Us

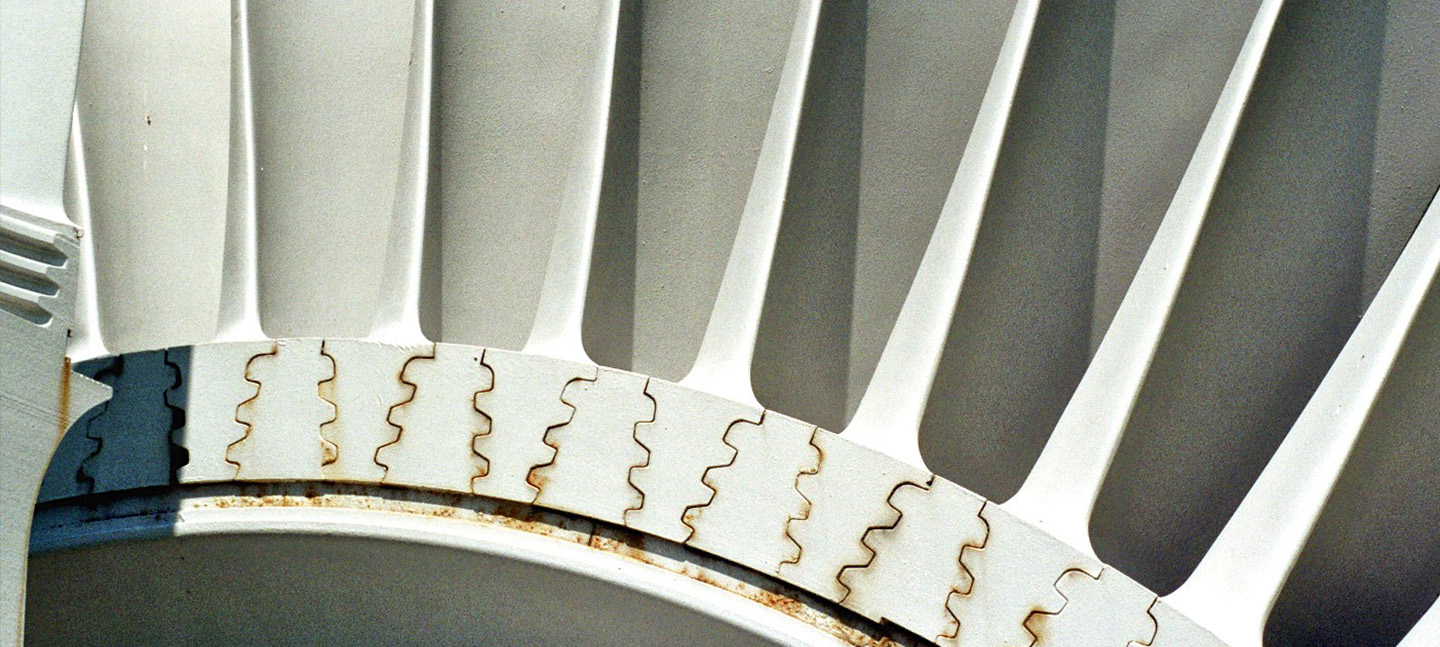

Innovative technologies

Innovative technologies

Client first approach

Client first approach

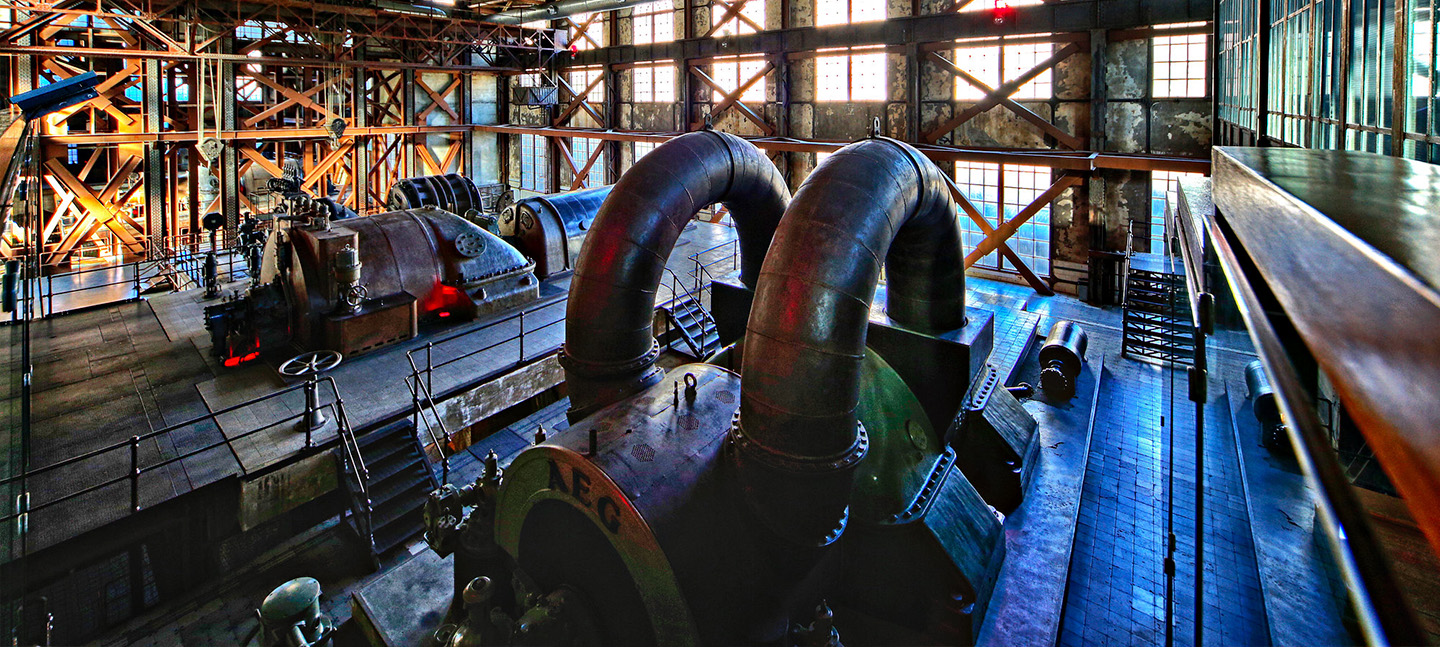

Equipment reliability and warranties

Equipment reliability and warranties

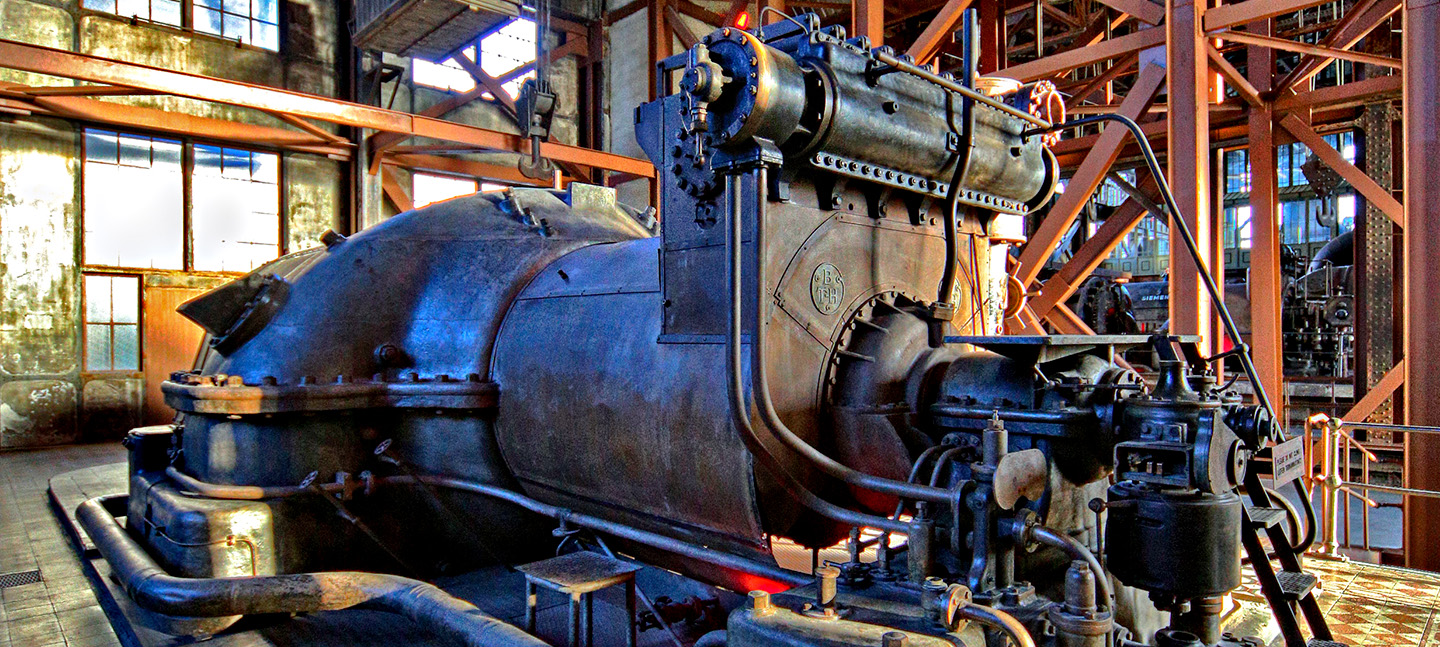

Flexible solutions with an option for retrofitting

Flexible solutions with an option for retrofitting

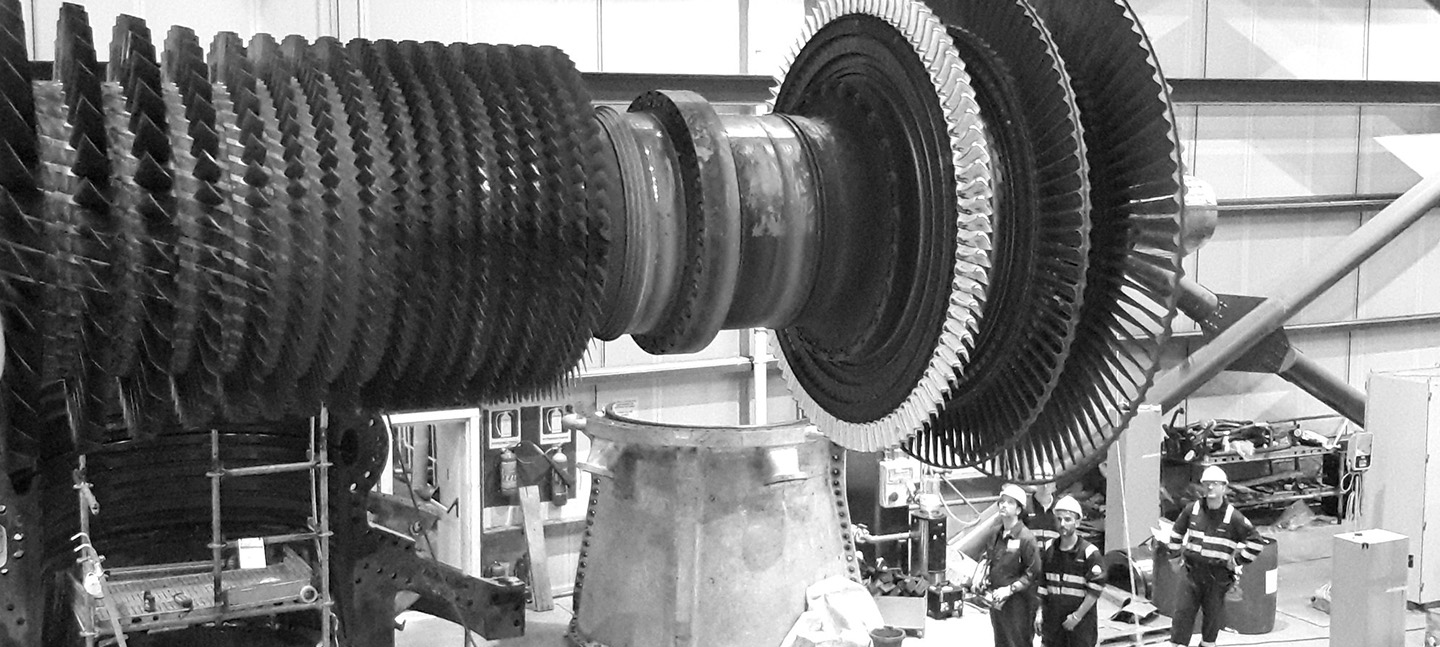

Industry experts

Industry experts

AKKOLADA Sp.z.o.o:

Is an integrator of process automation solutions, server solutions, uninterruptible power supply systems, embedded computers for various industries ‒ from industrial site survey to putting systems into operation.

Our work outcomes:

You will get a service package for turnkey automation of your production processes based on PLCs (programmable logic controllers) and automatic process control systems (APCS) produced by Siemens, Schneider Electric, Honeywell, Allen-Bradley, Wago and many other companies. We gained a thorough insight into the needs of industrial enterprises and therefore we are able to implement an approach tailored to the Customer’s expectations and requirements in terms of project performance and sustainability.

Our experts:

Stages APCS implementation

Develop software for controllers;

Design and assemble electrical control cabinets;

Perform installation and supervision works on electrics;

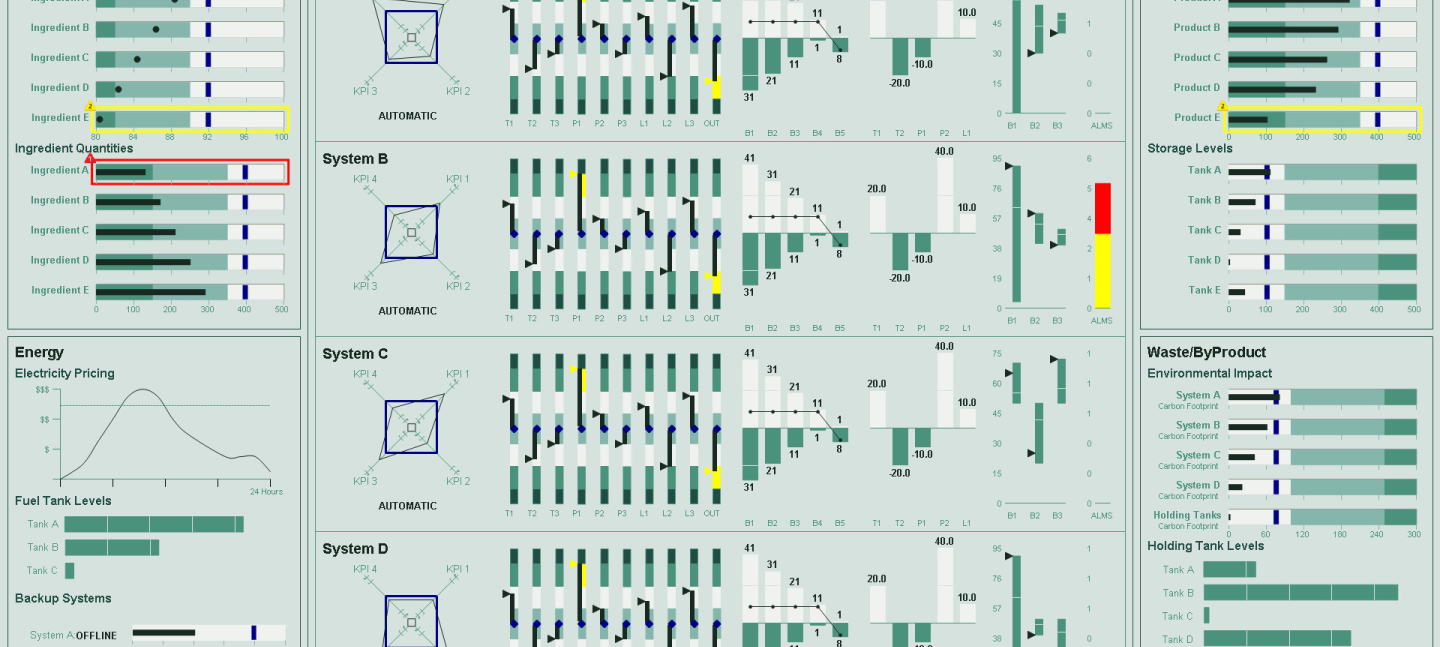

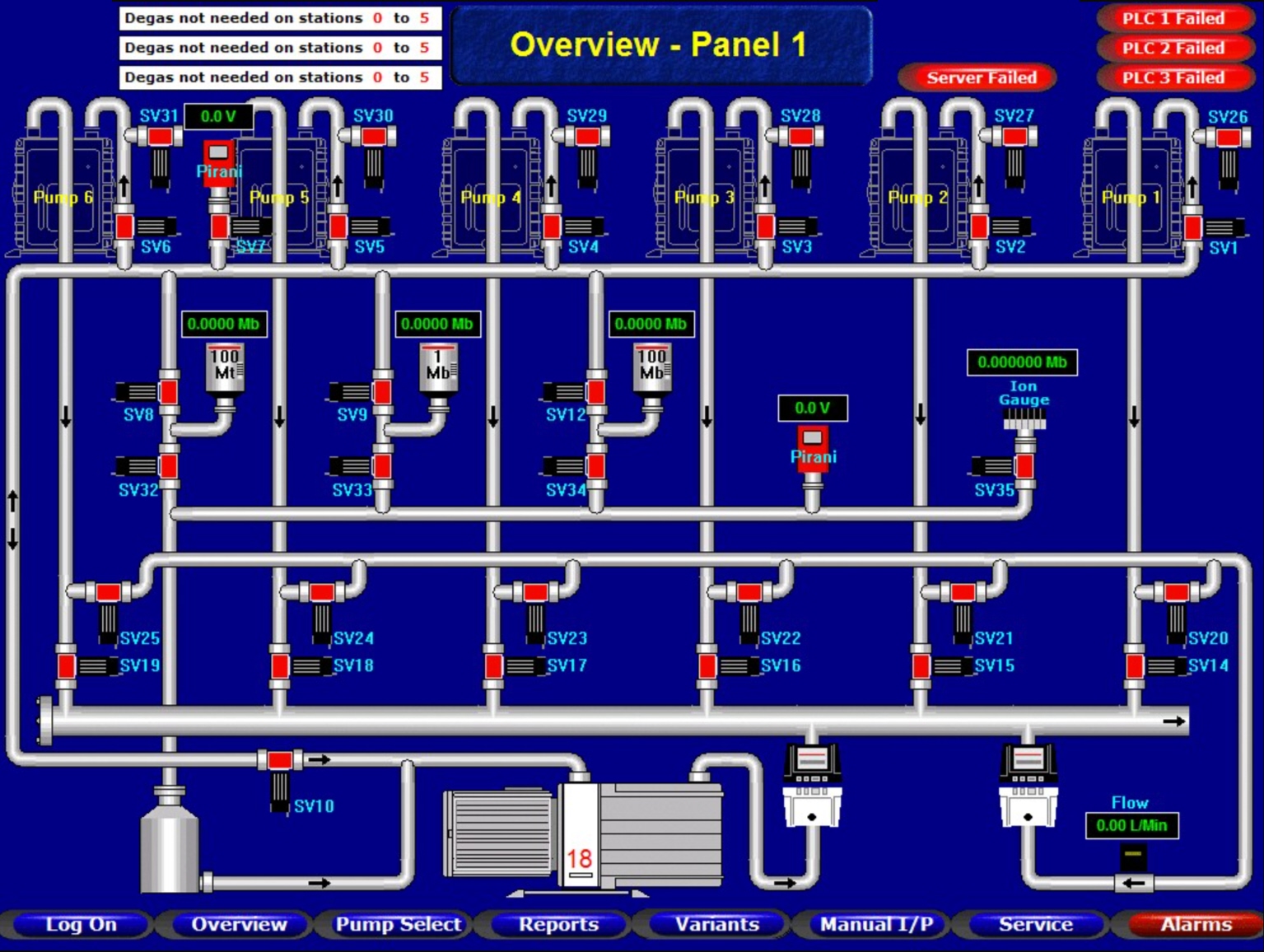

Develop display systems (SCADA);

Ensure logistics and delivery of equipment.Develop software for controllers;

1. Pre-project inspection:

1.1 Identification of the Customer’s automation needs;

1.2 Assistance in preparation of technical design specification;

1.3 Selection of APCS equipment for the assigned task;

1.4 Approval of the technical and commercial proposal;

1.5 Approval of solutions on equipment location;

1.6 Preparation of APCS structure diagram.

2. Design and survey works:

2.1 Approval of the composition of design documentation by the Customer;

2.2 Development of documentation on APCS

2.3 Approval of documentation by the Customer, compliance with comments.

3. Engineering works:

3.1 Configuration of PLC, control panels, operator workstations;

3.2 Development of control algorithms;

3.3 Development of SCADA system video frames;

3.4 Loading engineering results into PLC.

4. Construction and installation and supervision works:

4.1 Control of APCS installation;

4.2 Control signal cables connection to the PLC;

4.3 Power supply to APCS.

5. Start-up and commissioning works:

5.1 Pairing of signals;

5.2 Check of scales, settings, alarm system;

5.3 Check of correctness of display on video frames;

5.4 Functional tests of dynamic equipment;

5.5 Comprehensive testing of APCS;

5.6 Commissioning;

5.7 24/7 support of APCS for 72 hours;

5.8 Training of process personnel.

6. Maintenance and repair:

6.1 Equipment faults correction;

6.2 Modification of APCS at the Customer’s request;

6.3 Repair of APCS equipment in case of failure.

Our Services

9NEED A CONSULTATION?

99WE CAN SOLVE MOST SOPHISTICATED TASKS, AND OFFER YOU A CUSTOMIZED SOLUTION!

Partners